If your hydraulic equipment goes down due to failure in the manufacturing, construction or any Industrial setting, there is no time to waste in terms of getting back to production. You generally have two options, you can either replace it, or repair it. So, which one do you choose?

Rebuilding or repairing hydraulic equipment has been the route most companies have been choosing.

Let’s take a look at why repairing hydraulic equipment is probably your best option.

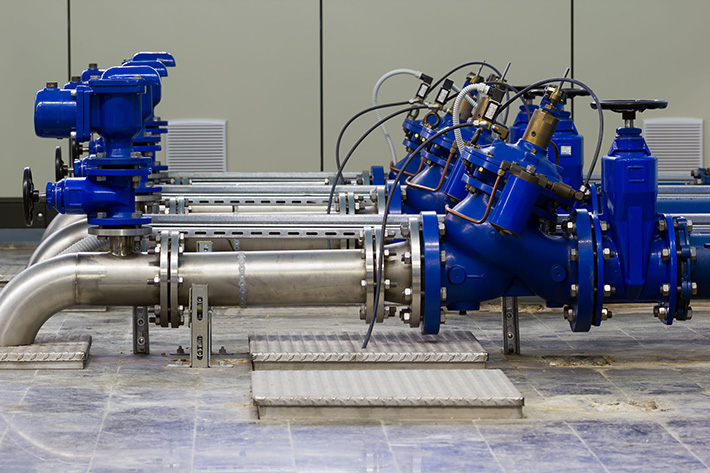

Repairing Hydraulic Equipment

There are a couple major reasons why you might want to repair hydraulic equipment over replacing it with brand new equipment, those reasons you ask? Time and cost.

Cost

Having a rebuild or repair of your hydraulic equipment is significantly cheaper than buying a brand-new replacement, repairs and rebuilds could cost less than half the cost of replacing.

Time

Rebuilds generally have much shorter lead time as well, which is incredibly important if there is a serious concern on how long your equipment is out of commission for. When replacing you have to consider you might be waiting for the new equipment to be manufactured, especially if this is a custom made piece of equipment, not to mention delivery times or sourcing if it’s not something common.

Rebuilding processes

When hydraulic equipment is rebuilt it is usually completely disassembled and every part is thoroughly inspected for wear, tear, and damages. Parts will be either replaced or refurbished to like new condition and up to OEM specifications. After everything is replaced or repaired the machine will then be rebuilt and tested thoroughly to be certain everything is in working order.

Rebuild Quality

Just because your equipment is used and had a failure doesn’t mean that a rebuild will be of low quality. Rebuilds represent exceptional value to used equipment and will be replaced with brand new parts and seals. The equipment will have a full inspection from top to bottom and all parts will go through evaluations to determine their life expectancy and if deemed faulty will be replaced. A rebuild can in some cases perform better than when it was new and in most cases, it can have up to 75% of the lifespan of a brand new piece of equipment.

Maintenance

Hydraulic equipment when maintained properly can last a very long time. But we all know in the industrial world that the hours can rack up fast on equipment and pass the recommended amount of hours for preventative maintenance.

Often employees won’t say anything until the equipment starts working unsatisfactory or even worse, when it’s too late and repairs are needed. A good habit to get into is to create an inspection log for your equipment and make sure everyone who needs to use that equipment is aware of it and abides by it. This will ensure that critical components such as hoses, connections, pipes and filters are regularly checked and signed off on. Along with the inspection log, a daily, weekly and monthly maintenance form that is signed by the workers helps immensely with making sure that things like fluid levels are satisfactory and high friction parts are greased.

Conclusion

At the end of the day it’s your decision whether you think you need to replace or repair. Repairing is the more popular solution and many companies have decided to go that route. But if time isn’t critical or if your situation dictates that the rebuild route isn’t for your company’s needs, then maybe replacing is your better option. Even with perfect maintenance of equipment, sooner or later you will come across this scenario, and we hope this article helped with your decision.

Servo Kinetics are experts in industrial hydraulic repair. We are a full-service hydraulic repair, inspection and rebuild facility that delivers the highest quality standards at the lowest possible cost. We have been in business for over 45 years and have worked with industries that have very exacting standards and include some of the most tech savvy companies in the world.

Our hydraulic repair services include Vickers classic factory rebuilds, Beach Russ repair, hydraulic field piping services and much more. We also provide reverse engineering services and manufacture new pumps and motors. Call us to learn more about our services and ask about our Special Offers!